Press Die

Performance/quality/reliability required by customers

We apply differentiated technology in relation to our product manufacturing.

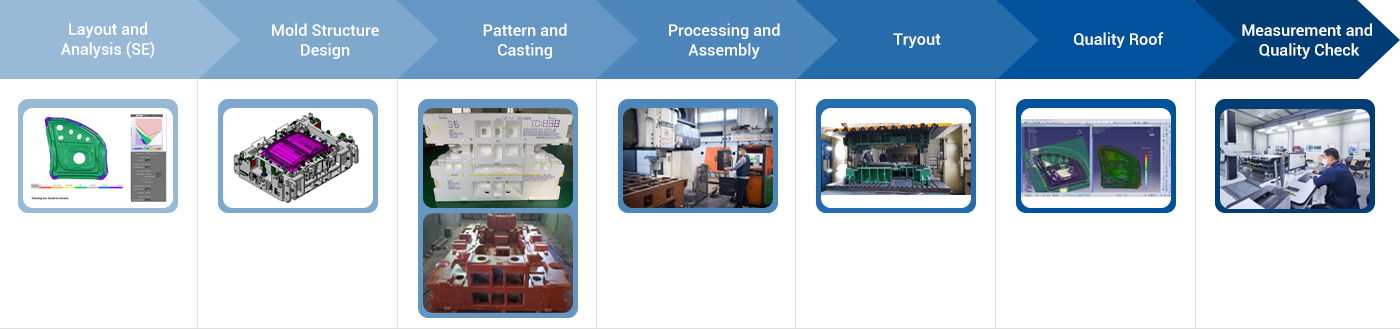

- Layout and Analysis (SE) Structural Analysis

- Mold Structure Design RP

- Pattern and Casting Property Evaluation

- Processing and Assembly DPA(Workability)

- Quality Roof GQMS

- Tryout Design standard

- Measurement and Quality Check Image Quality Review

How to respond to key customer requirements

Gain customer confidence by achieving quality objectives through pre-validation

-

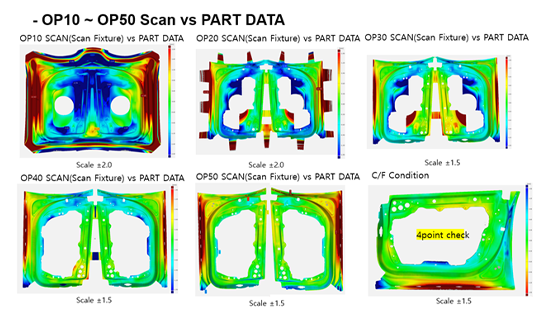

Quality Improvement through Reverse Engineering

-

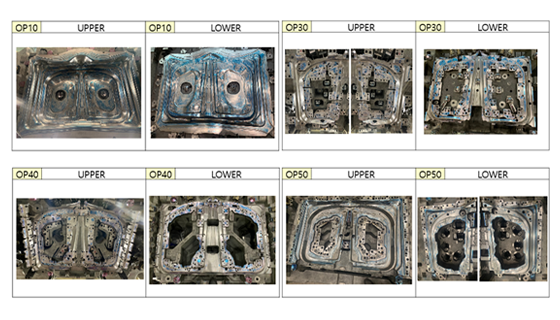

Product, Mold Scanning

-

Panel/Mold Measurement -CMM

-

Panel Measurement -Highlight Check

-

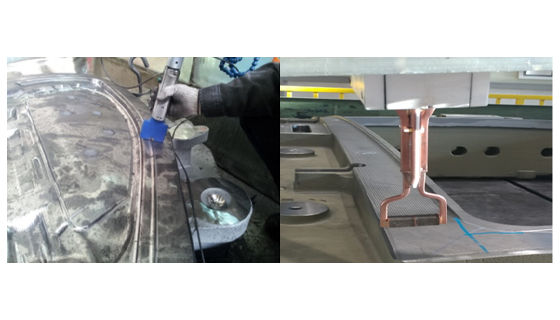

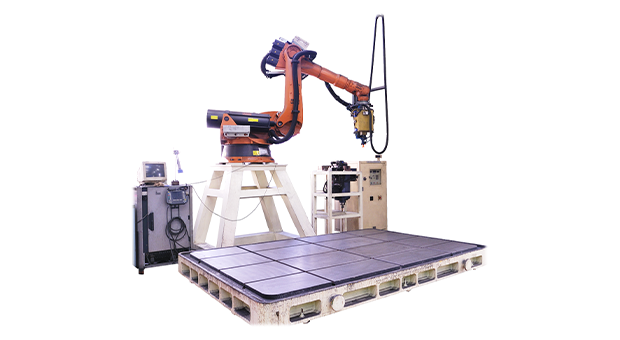

Induction Hardening

-

-

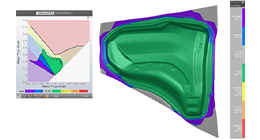

01. Method Plan Simulation

Software Qty Version Auto-Form 4 R10 Auto form Process design 1 R10 Auto form Triboform 2 R10 Please check with drag on both sides.

-

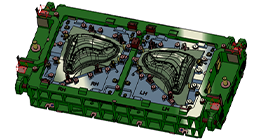

02. 3D Design

Software Qty Version CATIA 24 R29 UG 6 NX12 PRO-E 1 3.0 Auto-CAD 33 Ver. 13 VIZ Design 16 Ver. 1.5 Spinfire 10 - 3D Viewer 12 Ver. 2.1 Please check with drag on both sides.

-

03. CAD/CAM

Software Qty Version Power Mill 2 Ver. 2017 3D Pro 1 Ver. 3.5 NC Brain 2 - ALFO NC 5 Ver. 1.5 Z-Master 2 Ver. 2000 Please check with drag on both sides.

-

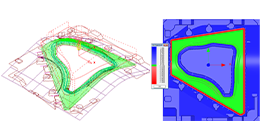

04. Scan&Applied Engineering

Quality Loop with Scan Panel - Process 1.Scan 2.Quality Check 3.Simulation 4.Comparison 5.Compensation 6.Quality Improvement

-

01. Method Plan Simulation

-

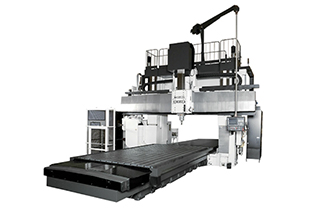

Model Brand Table Size RPM (MAX) Qty GL-27 APEC 5,000 x 2,750 15,000 1 MCR-B3 OKUMA 5,000 x 2,500 (3+2축) 6,000 (10,000) 3 RB-4NM SNK 4,000 x 2,000 8,000 1 MCR-A5C OKUMA 4,000 x 2,000 6,000 1 MDB-1 OKUMA 4,000 x 2,000 3,000 1 MDB-2 OKUMA 3,000 x 1,500 3,000 1 TOTAL 8 Please check with drag on both sides.

-

Capacity Brand Type Bolster Size Press Height Cushion Stroke Qty 2400 Ton WIA Mechanical 5,500 x 2,600 1,700 350 1 2000 Ton HWA IL Mechanical 4,800 x 2,500 1,650 350 1 1500 Ton SIMPAC Mechanical 4,500 x 2,500 1,700 350 1 1500 Ton HWA IL Mechanical 4,000 x 2,400 1,400 300 1 1200 Ton SY Hydraulic 3,700 x 2,500 2,000 350 1 300 Ton UGA Hydraulic 4,800 x 2,500 2,500 - 2 200 Ton HWA IL Hydraulic 4,500 x 2,500 2,500 - 1 100 Ton JEIL Hydraulic 4,000 x 2,500 2,100 - 1 TOTAL 9 Please check with drag on both sides.

-

-

CMM Inspection

CMM InspectionMaker Type Size Software HEXAGON Dual Arm 6,000 x 3,000 PC-DMIS Please check with drag on both sides.

-

Laser Scan

Laser ScanMaker Type Size Software LEICA Portable - PolyWorks Please check with drag on both sides.

-

Highlight Check

Highlight CheckMaker Type Size Software TOPMETAL - 1,600 x 2,000 - Please check with drag on both sides.

-

Argus

ArgusMaker Type Size Software ARGUS Camera - GOM Please check with drag on both sides.

-

-

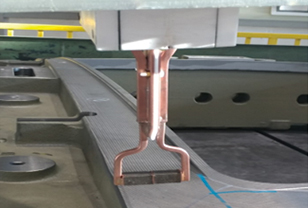

Material HRC Measuring Area FCD55 (GGG50, GM245) 42~ 45.3 - Bead

- Shape (over 10R)

- Shape (below 5R)

GGG70L (HD700, GM246M) 52~ 57.5 GM338M 50~ 56.4 Please check with drag on both sides.

TEACHING

TEACHING COIL EXCHANGE

COIL EXCHANGE HARDENING

HARDENING HRC MEASURING

HRC MEASURING