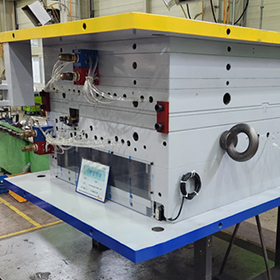

Injection Mold

-

STEP 01

STEP 01Product review

- Undercut check

- Check where contractions occurs

- Gate positioning

- Mold structure review (cooling, ejecting, mass production verification, mold TYPE)

-

STEP 02

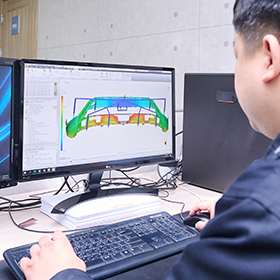

STEP 02Molding analysis

- Verify over 98% injecting balance

- shrinkage analysis

- Variation analysis

- Cooling analysis

- Verification of appropriateness for gate location & weld line

- Check gas occur point

-

STEP 03

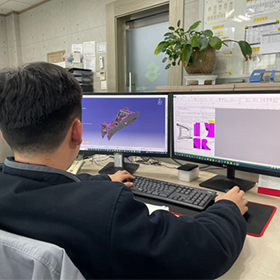

STEP 03Mold design

- Review method plan

- Production specifications review

- Structural design check sheet

- Complete mold design check sheet

- BOM check sheet

-

STEP 04

STEP 04Production review meeting

- Kick-off meeting for new project

- Production review meeting

- Mold workability review

- Drawing presentation

-

STEP 05

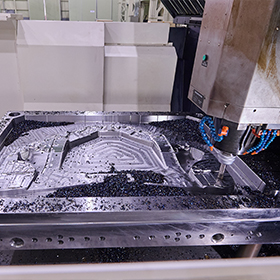

STEP 05Mold manufacturing

- Progress management (once a week)

- NC processing quality audit

- EDM processing quality audit

- Final mold polishing quality audit

-

STEP 06

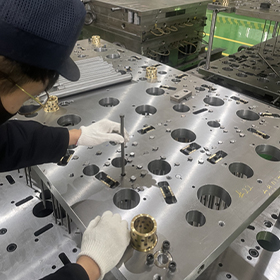

STEP 06Mold inspection

- the M/B check sheet

- the gun drill machining check sheet

- the boring processing check sheet

- the NC machining check sheet

- the CMM measurement

- the electrode machining check sheet

- the EDM check sheet

- Final mold polishing check sheet

-

STEP 07

STEP 07Parts inspection

- the core check sheet

- Eject pin check sheet

- Standard part check sheet

-

STEP 08

STEP 08Try Out

- Dynamic inspection

- T/O result report

- Injection specification report

- Part weight history management

- Injection ability audit

-

STEP 09

STEP 09Quality control

- Part skin quality history

- Part dimesion check sheet

- Dynamic & static inspection

- Final mold polishing check sheet

- Part quality audit meeting

- Mold shipment inspection

-

STEP 10

STEP 10Mold shipment